Mineral processing – Milling

Practical Action

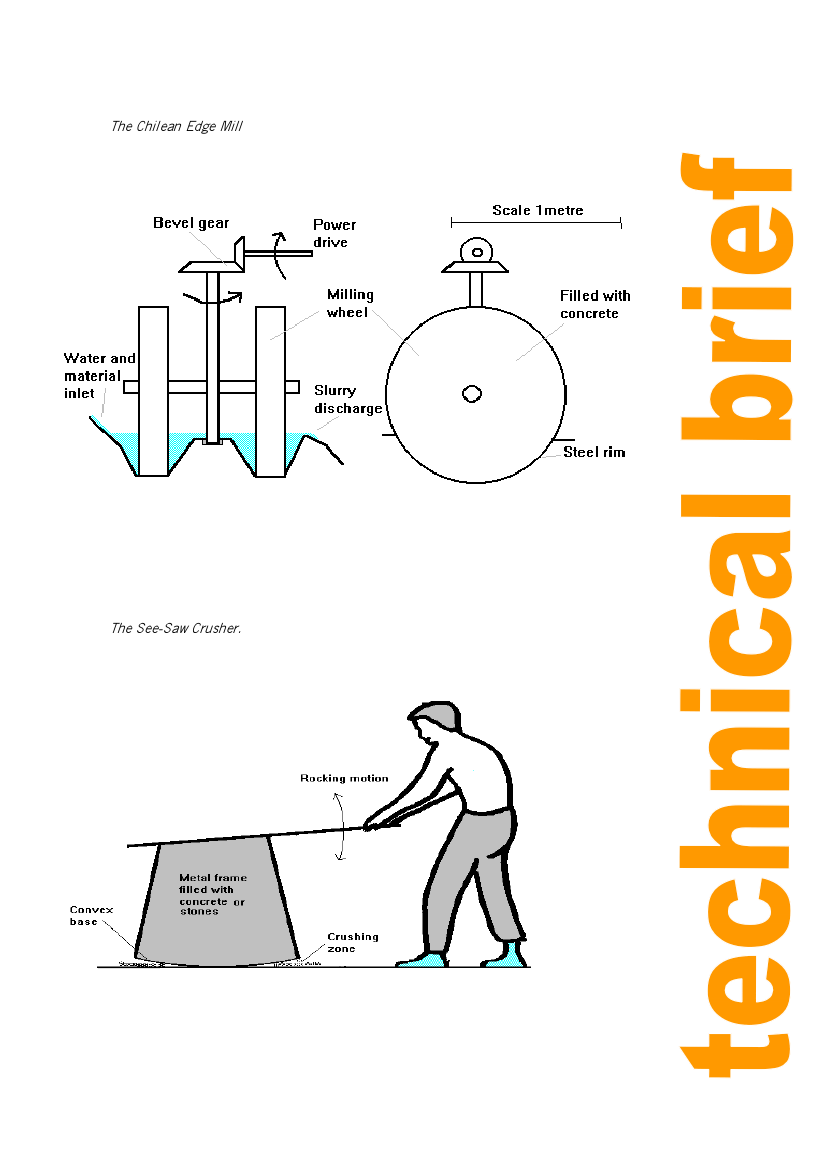

• The Chilean Edge Mill. Used commonly in Chilean gold ore processing, the edge mill

has two large steel rimmed concrete wheels (these would have been stone in previous

centuries) which roll around a circular concrete track and grind the gold ore beneath

them.

Figure 6: Chilean edge mill

Final product size can be very small and the final size is a function of the time in the

crusher. Grinding is usually carried out wet, the ore being washed in and out of the

circular track by the water.

• The See-Saw Crusher. Very heavy stone or steel ‘see-saw’ crushers are rolled over the

material which is to be crushed with the aid of a lever arm. The material is placed on

a flat stone or steel surface and the product is similar to that from a roller crusher

Figure 7: See-saw crusher

• Other traditional mills include pestle and mortar type mills and stamp mills, amongst many

others.

11